This post may contain affiliate links. Please read our disclosure policy.

words, interview & images // Nick DePaula:

As adidas looks to continue to affirm itself as a brand for creators, naturally, we’ve seen that take form in many different ways over the last couple of years. There’ve been full capsules with the likes of Kanye West and Rick Owens, to smaller scale launches and initiatives rooted in pushing the speed of manufacturing and process of design. The brand’s latest effort goes beyond just another tandem collaboration, as its partnership with Parley For The Oceans looks to create awareness for a bigger purpose ahead.

The New York-based Parley organization has since 2013 looked to bring together creatives and environmental leaders in conference settings to discuss new and innovative ways to reduce harmful plastics littering oceans around the globe. In teaming up with adidas, the two have set out to not only create footwear utilizing recycled plastic and other damaging materials, but have also created the first-ever soccer kits made 100% from recycled ocean materials.

The New York-based Parley organization has since 2013 looked to bring together creatives and environmental leaders in conference settings to discuss new and innovative ways to reduce harmful plastics littering oceans around the globe. In teaming up with adidas, the two have set out to not only create footwear utilizing recycled plastic and other damaging materials, but have also created the first-ever soccer kits made 100% from recycled ocean materials.

“At this point, it’s no longer just about raising awareness. It’s about taking action and implementing strategies that can end the cycle of plastic pollution for good,” says Cyrill Gutsch, founder of Parley For The Oceans.

While today’s launch of the adidas Uncaged UltraBoost Parley will be limited to just 7,000 pairs, the plan ahead in the next year will be much more robust, with more impact to be felt across the oceans.

“This represents another step on the journey of adidas and Parley For The Oceans,” declares Eric Liedtke, adidas Director of Global Brands. “We will make one million pairs of shoes using Parley Ocean Plastic in 2017 – and our ultimate ambition is to eliminate virgin plastic from our supply chain.”

This first commercial launch marks a strong pursuit of sustainability, as the Uncaged UltraBoost Parley is made up of 95% recycled ocean plastic and 5% recycled polyester. In addition to the million pairs of sneakers created with similarly recycled ocean plastics on deck for next year, adidas also plans to retrieve and repurpose “at least 11 million plastic bottles into elite performance sportswear.”

To hear all about the brand’s new strategy around high-level collaborations and its approach to creating footwear and apparel out of new knitting processes with Parley, Nice Kicks recently caught up with James Carnes, adidas VP of Brand Strategy Creation. The shoes go on sale at 7 AM PST on adidas.com.

Nick DePaula: The Parley partnership represents a bit of a different approach by the brand. How has your role in the company shifted and how has that influenced some of the projects we’re seeing come to life?

James Carnes: I actually was in the design department for twenty years almost, and about 21 months ago, we reorganized and started a new strategy department. The cool thing about it, was prior to that, strategy meant logistics and planning – something that I would’ve had no interest in. [laughs] The new team is a brand strategy team, so we’re focused on creativity and the future of planning five, ten and fifteen years out. That sounded really interesting.

One of the first things that I worked on was our SBP, which is our Strategic Brand Plan. A couple of the key choices that we would make that would really change the brand for the future. We ended up with three things, and one of them was how we would localize ourselves in cities. We found that the growth of cities would really be how we could become more territorial.

The second one was how we would get closer to consumers with production and the idea of speed. How do you talk to people, collaborate with them and get their ideas and turn product around quickly with our SpeedFactory? The third one was how do we do all of that through this idea of Open Source? How do we actually collaborate with people, designers, creatives, athletes and partners.

What was cool, was a lot of the work that we had been doing for years was dabbling in that territory, but didn’t have a home. What came out of that was we had a different strategy for how we could launch that stuff. Paul Gaudio, who is our Creative Director for the brand, worked with the team and created this vision around what it means to be creating the future. How do we take all of these collaborations and co-creation opportunities that we have and how do we define them.

The biggest thing is that we want to be open. Sometimes you see a collaboration and it’s Brand #1 x Brand #2. A lot of it can be really static. Who are we, who are you, and then we put that together. What was cool about this was we approached it by going to people and saying, “This is what we have and what we do, what would you do with it?”

It was a totally different thing, where we would bring the ingredients and a list of things, and then put that in front of people. It’s more about co-creating instead of what collaborations have been.

NDP: How did the opportunity with Parley For The Oceans come about then?

JC: We get stuff sent to us all of the time. Sometimes that’s a 7 year-old kid who says he wants to design shoes, and how do you tell them no? Or sometimes it’s a supplier that says, “I have a special shoe lace!” We made a shoe last year at the United Nations, because ocean sustainability was one of the items being discussed at the summit. Cyrill Gutsch is the founder of Parley, and he’s a passionate dude that changed his entire life to be preserving the oceans.

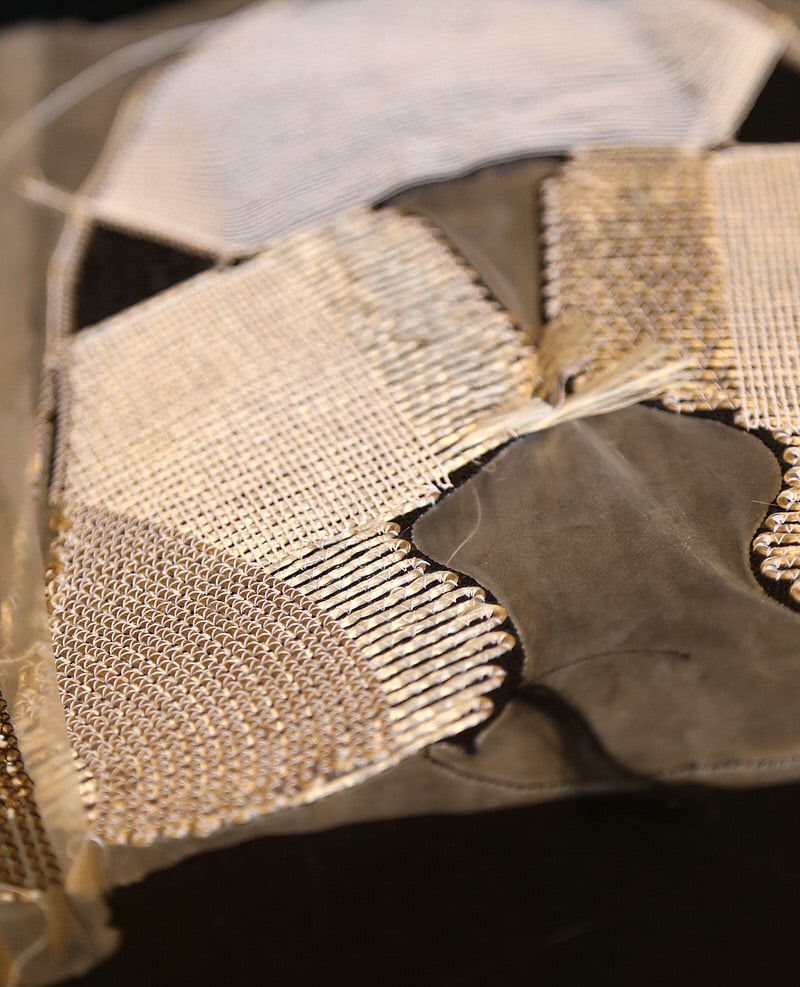

While working on that project together, we ended up with 72 kilometers of abandoned poacher’s net that was retrieved by Sea Shepherd, which is a group of about 80 people that spends ten months going around and protecting the ocean. For about 24 days straight, the entire crew went through shifts to pull these 72 kilometers of nets onboard.

These fishing nets are super high grade nylon, to the point that when you’re recycling it, you’re getting something that’s a higher grade than what you get from many injected parts. We made that United Nations sample in less than six days as an experiment, and it’s not built for performance, but we wanted to see if we could be the first to make a shoe out of recycled nylon and other recycled content. The upper is 100% recycled ocean plastic, and then we brought in materials people and other designers to all work on different parts of the shoe at once.

The first time I met with Cyrill, we had these 72 kilometers of nets, and we were also looking at using different knitting machines. We had new machines that could go from knitting fine yarns, to even thicker cables through the upper. We had done all kinds of samples with exaggerated cables too, like electric cables, fiber glass and even carbon fiber, just to see if it could be done. I took all of that and I said to Cyrill, “You know, I think we have a process that can take all of this stuff.” So we actually broke down the nets, broke it down into a spool of filaments and then made a yarn from that.

NDP: The Parley project started out small with only 50 pairs available through a giveaway, but then grew to be more mass. How has that partnership evolved together?

JC: It’s really about the power of what happens when you put all of these people together that have an expertise. I was a designer for years, and you want to feel like you’re somehow the genius that has an inspirational idea, but it’s so much more satisfying when all you are is the head collaborator that can pull all of this stuff together and make something new.

There were a lot of questions around, “Well, why can’t you make more?” And where we started, there was a machine literally downstairs and it was the only machine that could do this. We had it set up to do exactly what we wanted to do, and there wasn’t one in Asia anywhere. We made those uppers here in Germany and then it gets sent to another factory for the final shoe to be assembled.

The plan was to scale it up. There’s two paths for that. We could take the yarn and put it in a more commercial version, [which we’re doing now]. The other path is to develop the technology, and do more with the tailored fibre, filaments and yarns that we could put into the product in a totally different way. We’ve really started to co-create materials and yarns with Parley that can help us to create the product in a unique way going forward that’s different from what we normally do in our factories.