This post may contain affiliate links. Please read our disclosure policy.

NBA vet Langston Galloway has done things a bit differently and that applies to the performance basketball industry as well. Teaming up with sneaker designer Brett Goliff, they’ve launched Ethics, an independent sneaker brand, and Langston’s signature sneaker the Ethics lgONE and we sat down with both of them about the sneaker and how it all came together. This interview has been edited and condensed for clarity.

NK: How did Ethics come about and how do you guys get connected?

LG: So we go all the way back to Sneaker Con, think that was 2017 or 2018.

And then fast forward to me, playing with the Pistons my first year there and I had the inclination of, “I got to reach back out to him because I was working on what was next for me.” So reached out to Brett and was like, “Hey, I think I might have something here where I can kind of take over creative control and kind of do my own thing.”

We met at a diner, one of the famous diners in Detroit, and I brought like 8 pairs of shoes and a bunch of sketches, and it kind of started a great relationship, a great friendship. Fast forward to now, a brand has been launched and we’re just taking it one step at a time. And we didn’t even have a name at the time, Ethics wasn’t even thought of. It was just like, Hey, we’re going to figure out as we go, just create a shoe, that’s all I kept telling Brett. Look, don’t worry about the name, let’s just create a shoe.

So going from creating a shoe to probably over the last, I’ll probably say, like six months, seven months, that’s when we kind of started saying, “Hey, we might have to start like throwing ideas at the wall about this name. What can we come up with?” A ton of names came across the board. We just threw stuff at the wall and I think I think Brett or my wife, one of them, came up with the name Ethics and we were like, Hey, that kind of resonates. A word that could stick to a lot of people and stick to my story as well, that was the biggest thing, having a story behind the brand so why not Ethics? That’s what I came from, my upbringing. But then also to just the story behind it because I was undrafted had to find my own way and just to stay the course. And I think that’s where Ethics kind of creates its own name, its own identity. And a lot of people can get behind it can really see themselves inside this shoe. So that’s why I’m really excited about, taking it to the next level and seeing where we can go with it.

NK: And Brett, if you can give the readers a quick introduction of who you are and what’s your history with sneakers, your sneaker design career, and how it came together from your perspective.

BG: So I’m Brett Goliff and I have footwear design consultancy. I’ve worked with a lot of brands that’s been going for about 10 years. I’ve done I do a lot of vision work for a lot of brands. I’ve been doing that for a decade and I was at New Balance previous to that. I’m also in the automotive industry. That’s kind of the day job working on Chevrolet, Corvette, and Hummer from the color and trim design scenario. But from my standpoint, Lang and I kind of came together organically. I mean, it was probably one of the most random walk up things ever. We were at Sneaker Con and I’ve done a lot of sneaker media and other stuff too over the years, and we had friends that were all within it, and he walked up and started talking. We introduce each other and then I don’t remember if we exchanged numbers, but we just exchanged our Instagrams.

But from that point, we just kind of kept it going. It was beautiful for me and we met at that diner because just imagine two people at a diner that’s packed. And then he brings in this massive-sized bag and brings in all these shoes and everything, and we’re just sitting there for like six hours just talking shoes. And it isn’t that different than what brought you into the love of what you do, right? Just that conversation and that that that feeling. And from there, I feel like it’s been the blend of what is beautiful about modern technology, anything from us recording videos of like a shoe that we have in hand and talking about it to texting to Instagram, private messages, to phone calls, to Zoom meetings, all the stuff we just do whatever we can to stay in contact and communicate. It’s really been a beautiful journey.

NK: Bigger brands have their own technology and design language they can lean on but as an independent sneaker brand, what was the design process like for you guys? And what are some things that you learned about the sneaker-making process that you never really thought about before?

LG: Having to go through all this with COVID going on, was the biggest thing. We were having Zoom calls left and right, just trying to bring ideas to the table and not being there physically to kind of go back and forth on it on a table and sketch things out and talk. Everything was off of Zoom and phone calls, FaceTime, you name it, trying to figure out. “Hey, what can we compare this to? What can we make it something that is our own, not just copying off of somebody else’s?”

And then, going through so many different like calls with the factories and trying to figure out, “Hey, what’s the best manufacturing for us?” A ton of things just transpired, and I think that was the beauty of it because it’s not the progression of getting better and learning and figuring out things. And bouncing ideas off of each other saying, “What do we want to add to the bottom and outsole of the shoe? How can we perfect that and make sure that’s good for performance? How do we want to be different? How do we make it a cut and sew shoe different from a lot of shoes that are made today and kind of bring the nostalgia back?” I think that’s where we kind of want to be different. We wanted to bring back that history, but also create something new, that a lot of people can kind of resonate with, but also to our own legacy.

BG: I think to add to that, I’ve had a lot of experience in helping launch small brands and other pieces. As your reference to like major brands like, mold costing them really isn’t that big of a deal, but that’s really our greatest hurdle. Knowing Lang, knowing his playstyle and breaking down conversations, and just having tons and tons of one on one conversations to understand what comfort really is to him. That’s a key thing. Comfort to all three of us is likely different, that’s an opinion. So being able to understand what he was trying to solve for and what he was going through.

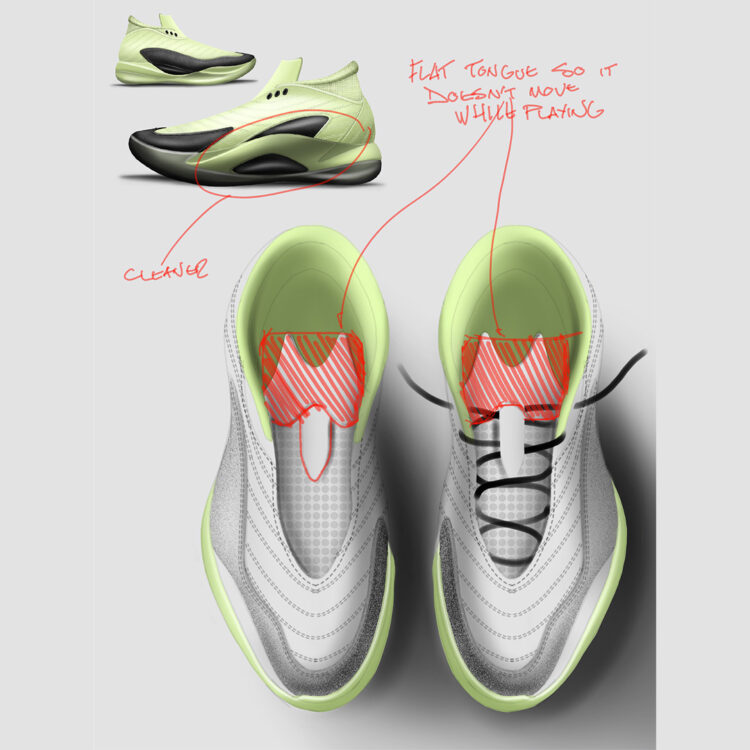

The other part that I would say to it is we knew, as you kind of mentioned, technology is an interesting thing. We don’t have a research and development fund. So we had to come up with what we knew was great and how we can make it. And a lot of that came down in the shape of our last. We really focused on creating something that was very modern, very contoured to the foot, having a beautiful shape. I think a lot of times when you think of a cut and sew shoe, we have memories of most of us growing up 80s, 90s, that type of basketball shoe and that product. And it’s beautiful. There are things that we fall in love with, but you can definitely tell that the shape is is to that era as you go through it.

So we focused on bringing this real modern piece that would really secure around your foot and the cut. Also, it was partially making sure that we were maintaining our costs properly, but it was also looking at the court. We knew that if we were going to offer something, the world doesn’t need another product. Just to be frank, if you’re thinking of sustainability, it doesn’t need one. But we needed to make sure that we had an opinion on what we were trying to do and the cut and sew really set us apart. Lang was able to be in the Finals last year, which was an amazing blessing for himself and the brand. And when you saw that shoe on the court and you saw it on camera, there wasn’t anything else that looked anything like it. That was it’s a phenomenal feeling and it still is that way when you see him playing right now, too. So that was one major point, and it really helped to set us apart because we are going direct to consumer, which is a beautiful thing that we have. So you won’t find us necessarily a Foot Locker or anything like that but if you put it on the shelf and you put it next to the other shoes that are out on the market, there isn’t anything that looks like us.

(Photo by Joe Murphy/NBAE via Getty Images)

NK: Kind of expanding on that, since there isn’t a huge R&D budget and patented tech as far as cushioning, what was there a wear testing process in all of this?

BG: If you’re a major corporation, their R&D can go and like, “Hey, let’s figure out how we’re going to make somebody jump higher.” We don’t have that type of R&D, right? What we have is a knowledge of great product, and we cut up a bunch of shoes. I mean, tons of shoes, anything that you can think of. Lang has a specific mind and a great history of basketball product, so he knows what felt good on your foot. So while we don’t necessarily have, say, an Air or whatever you want to come up with for your terminology, we do have a dual compressed midsole. Meaning that it is two durometers of foam, which is pretty innovative. And what we focused on was where those durometers felt and fit. Going under the forefoot and going under the heels, so one that’s a little bit more firm and then one’s a little bit more for cushioning. It is a very advanced way of manufacturing. Also doing a TPU plate that’s going to lock in midfoot but closer to the fifth metatarsal heads coming further into the forefoot and then the arch piece. One thing that we want to focus on was flat foot, making sure that it did not collapse underneath you.

So there was a lot of innovation and research that went into that. I think where we got lucky, we were able to find a factory that worked pretty rapid and worked with us pretty quickly. And having a professional basketball player being able to be our wear tester was really where it came down to. He spent about a year and some change in the shoe before we actually hit production and that those notes were precise. From our history of both of us just being in love with the sport and basketball, we knew what we wanted to do tread pattern wise through my history of creating product and his history of wearing product, we knew what would work wouldn’t work. So that’s really how we came to that, that scenario. So yes, we don’t have a full R&D budget, but I guess what I mean by not having an R&D budget is not having that exploration time, right? We knew what we had to execute is the best way of saying, but I’ll let Lang hit on how he wear tested and what he did because it was pretty beautiful for him.

LG: That’s what’s special about the wear testing part important because we kind of went from having just one shoe, for just one foot. “Let’s just try this on the left foot.” Put it on. “It’s OK.” Needs a little adjusting and send it back, or they send another one. All right, now we have to wait and see. “All right. Is this good?” Let’s put my insert in there. And then it’s just a process of one thing at a time, and it kind of just built up until we have two shoes like we have our luck and we have a right foot. And then going from there to like, “All right, OK, we need to add a little bit more tension here or we need to add or take away something right here. So it feels comfortable.” I remember we had a heel issue at the beginning. We were like, “We got to change this to make sure that it feels better on my heel when I’m playing.” And then when we figured it out like, “OK, all right, this is money.”

Now it’s time to take it from there, just walking around in it to let’s take it to the court. And I think that’s where I’m at a different space than a lot of guys because being an NBA athlete like nobody else is doing something like this. Nobody else is trying to go from the ground up to being able to wear my own shoe, nobody else can say they’ve done that.

Nobody else said, “All right, I’m gonna put this on the court and see if this works.” And it’s like, if it falls apart on you, it falls apart on you. It’s just like you have to have to take those with a grain of salt and just say, “Hey, let’s see what happens.” But that never happened. We just continued to roll with it and then I started practicing them and then people started asking questions, “What do you got going on? What are you doing with it? What’s this? What’s that?”

Looking back on that process and now people reaching out to me and saying, “Hey, how did you guys come to this? How do you how did figure this out?” I’m like, “Hey, I’m an NBA athlete. I’m wearing them in the games. There is no other wear tester that can speak for me. It’s me.” Hey, look, if I’m able to wear, I’m on the court. I feel like anybody else. So that’s why I think that we differentiate ourselves from a lot of different companies and we’re doing something different.

BG: It’s truly athlete tested. The other thing that we both forgot to hit on is we focused on being able to have the insole be removable and fit in a custom orthotic if you need it. We have a very good insole in it so if you’re ready to play with it, but if you need to go above and beyond, that is available for you as well.

NK: And Brett, I know you mentioned earlier, you do have a day job working at a Chevrolet, and there does seem to be a correlation between sneaker design and car design. Were there any like design aspects or inspirations that kind of came from that into the lgONE?

BG: I kind of always joke that I’m always stuck between like two modes of transportation somehow, whether by foot or by auto, I suppose. But I wouldn’t say that there was a direct automotive correlation, I think it was just a coincidental event. I guess both of us being in Detroit, in the Motor City at the time, that really helped a lot because you got that one on one connection.

I think realistically if I have to give the true driving inspiration behind and was that when I presented it to Lang, I used an Andre 3000 quote where he talked about real cars used to be made out of metal and stuff. This was like a real focus to go the exact opposite of what the industry is doing right now. And I think that that that doesn’t come back to automotive directly, but automotive is all cut and sew on an interior of a car and other things like that, right? So there is that element, but there isn’t something that I could say to you like a Ferrari.

Knowing the craft and quality of what the shoe is and how are we going to put that around the foot, I think one of the things that we haven’t even talked about yet with anybody or even Lang and I internally, but wearing my pairs around a lot, one of the big sneaker scenarios is like, everybody hates it when it creases, right? It’s a very big, frustrating piece. The way we’ve designed this is because it’s pattern-based and how it flows around the foot and then you’ll notice they’re stitching that goes throughout it, that like parallel that you’re not going to see a ton of that. And it’s really just because of the way that we cut the pattern and work through it. So if anything, it was inspired by the craft and quality in the way that you can make a shoe and make it perform at a high level.

NK: The performance basketball market is pretty much dominated by two or three brands at this point. Do you feel like there is room for like independent sneaker brands in that sector? What do you think is the standout feature as far as standing out from a performance-based market?

LG: I think for us, we wanted to say we’re not competing against the bigger brands because, you know, that’s hard to say. We’re a startup, we’re just getting started, we’re a long way from that. But at the end of the day, we wanted something comfortable but also looks good. Something when you see the shoe they think, “OK, they put a lot of effort into it.” Those are the details that we wanted to focus in on and I think that’s kind of how my game is. I don’t want to say and speak too much into my game, but my game is all about the details, the cutting angles to get to a spot at a certain point. Or being able to lock in and play defense on somebody. That’s the message behind what we wanted to like hammer down on, the details. This is the best way and the only way we can kind of go because it differentiates me. I’ve been different my whole career, going undrafted, finding a niche in this league, and being an eight-year vet. That’s where we looked at it like, how can we put something together that we know that this is different, something that people will say, “Oh, this stands out.” This is something that makes sense for a lot of people that they haven’t seen in a while. And that’s where I think that’s where we want to go and kind of hit the nail on the head.

BG: I’d like to add to that. I mean, look, the goal is to be ultimately in a major successful company, right? We want that. We want to see that grow. We want to offer our own views and opinions on what footwear is. I just know internally from our conversations, we don’t have a goal to be selling a billion shoes a year. If something like that would happen is great, but I think when you sit and look at the market of other competitors, and I don’t even want to call them competitors because I don’t think we look at it in that way, their focus is much, much more than just creating a great basketball shoe. It’s marketing a brand, it’s marketing a company. We’re trying to create something that is harnessing a community, harnessing something about the journey like Lang just completely laid out.

There are far more people out there that don’t make it to the NBA and the people that do make it in the NBA. And it’s beautiful to have somebody that’s had that journey of going through almost all elements of basketball and life and what kept them going through it. I think to me that’s true is a representation of it. As he and I were talking about it, and as we build it, the way I kind of look at it is like we may not become like a major, major thing, but we want to become like that phenomenal Farm to Table three-star Michelin star restaurant.

Still know your product, you know your customer. You may have a waitlist that’s like out a month and a half right of reservations, but we have this thing that we can communicate and work with people and be a part of that community. I don’t think we have any desire for it to become this major huge thing. And I actually think the thing that’s beautiful about Lang as well is we’re all fans of footwear. Every one of us that are on this call, obviously, and everybody that’s going to be reading this, you can go follow Lang on all the channels. He’s still picking up product that inspires him and makes him things different. Ethics represents him on the court, but there was other stuff that’s outside of it. We’re not giving up on that and say that this is the only way to do it right.

NK: What’s next for Ethics?

We have the second shoe we’re working on right now already and we got five more colorways of the lgONE and we’re already brainstorming on the third. This is going to keep going and it’s going to be a good foundation and we’re hyped for it.

(Photo by Nathaniel S. Butler/NBAE via Getty Images)

The Ethics lgONE is restocking on ethicsthebrand.com on February 3rd with a retail price of $120. Much thanks to Langston and Brett for taking time out of their busy schedule to talk to us about the Ethics lgONE.