This post may contain affiliate links. Please read our disclosure policy.

Six years ago, when Dominic Chambrone wanted to learn how to create custom sneakers, there was nowhere for him to go. So he decided to get in his car and drive from his home in Santa Rosa, California to Ashland, Oregon and spend $5,000 to learn the art of shoemaking. From that initial course, he took the centuries old art of crafting footwear and parlayed it into a career of making custom sneakers. Back in August, he hosted his first ever Decon/Recon Workshop in Brooklyn and this past weekend fourteen students from all over North America flew to Downtown LA to take part in his second class.

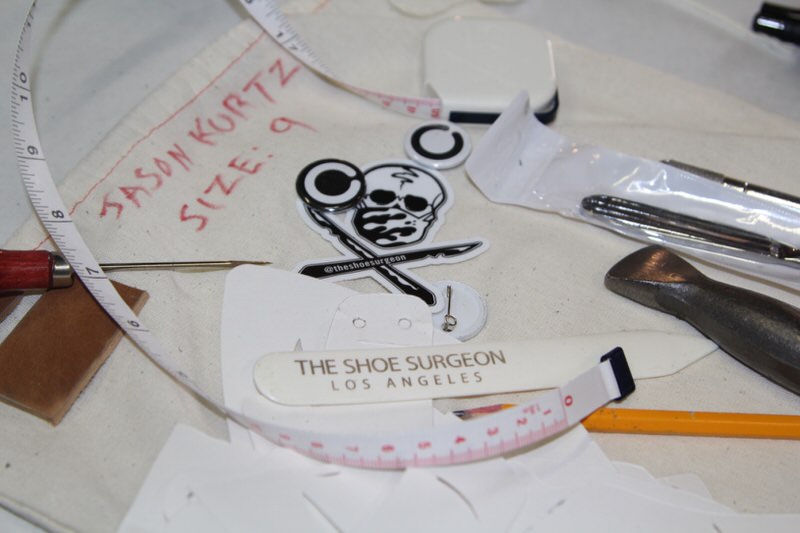

Dominic provided each of the students with a 100 piece tool kit and either an Air Jordan 1 or an Air Force 1 to deconstruct. Students carefully removed the sole of their shoe as that would provide the base for the creation. Then they were instructed to remove the stitching to take apart each individual section of the shoe. These individual sections were then used to create a pattern that the students would use to cut out the leather pieces to create their shoe. Student, Alex Sax, stated that this part was one of the most challenging of the workshop. “It is way harder than anyone would think. Creating the patterns was incredibly time consuming and tedious.” Sax had previously taken a class at Mood (LA fabric store mecca) and was familiar with textile projects in the past.

Ecco Leather from Amsterdam provided a wide array of premium leathers for the students to choose from. Some students, like Sax, came in with a notion of what type of design they wanted to create. His choice was a version of the Fragment AJ1, while fellow student Aaron Childress wanted to “do the reverse Shattered Backboards and freak it!” Other students let the materials guide them into what they wanted to create. Ruben Alvarez, founder of Rufnek Clothing, was inspired as soon as he saw the white, full grain, pebbled leather lying on the table.

Next in the process was layering the pieces together that would need to be glued and subsequently sewn. Pictured below is an all moss green Air Force 1.

Gluing may seem like the easiest step, but placement of the layers is critical to maintaining the proper proportions of the design. Also important is applying the proper amount of glue so that the layers adhere to one another, but not so much that it seeps out onto the upper. Once glued, the pieces are left to dry before students may proceed to flattening and sewing stages.

The stitching together of the uppers was by far the most challenging part of the process according to the majority of the students. Choosing materials that were too thick or designs that required rounded edges led some students like Andrew Tahm to modify their original designs. “I decided to switch up the Nike Swoosh to a Bapesta Star simply because it is much easier to sew straight lines.” Trial and error at its best.

While many of the students took the $1,750, five day course for the incredible experience alone, some, like Allison Haggins took the course with dreams to pursue a career in sneaker design. “I attended FIDM and currently work as a Design Assistant at Chinese Laundry. I have been interested in footwear design for a long time, so when I saw Dominic post this workshop on Instagram I knew I wanted to take it to learn from the best.”

Dominic’s ultimate goal in hosting these workshops is to teach his craft to others so that the custom sneaker industry can flourish. He plans on hosting more of these entry level workshops, but also expand into Master Classes for those who truly do want to make a career out of shoemaking.